Mechanical and fusion splicing are two, widely used fiber termination techniques. Each one of these splicing methods has its requirements, method, advantages, or disadvantages. However, fusion splicing is becoming the preferred splicing method.

Difference between Fusion and Mechanical Splicing

Splicing through Fusion:

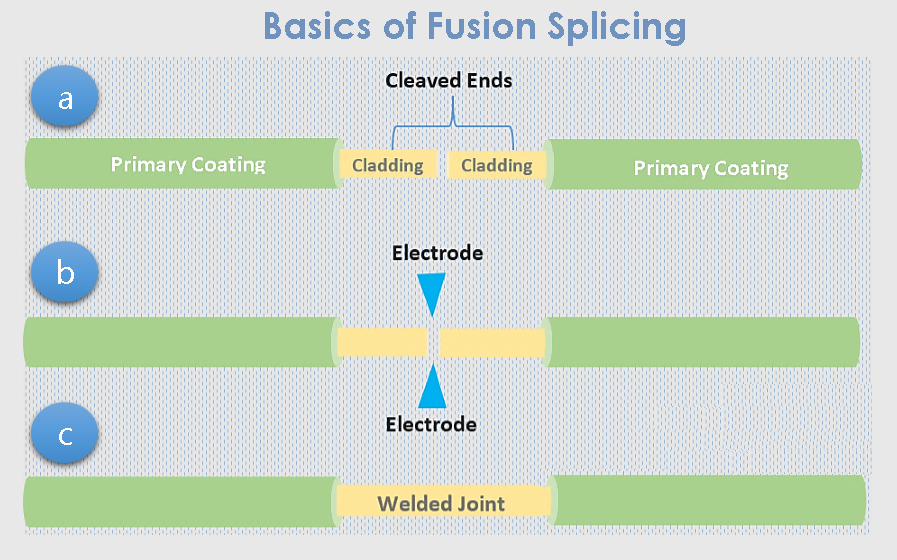

In fusion type splicing an especially designed machine aligns two separate fiber ends before “welding” or “fusing” them together by means of an electric arc. This mechanism ensures an excellent connection. New splicers available today are capable of handling solo as well as mass fusion operations. Thus, you can proceed with either one fiber or with up to twelve fibers in a single operation.

Mechanical Splicing

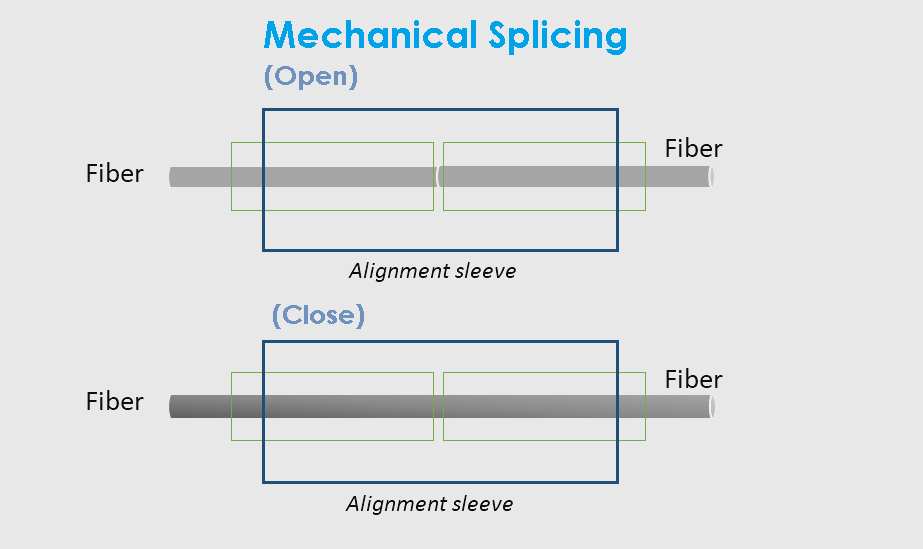

In mechanical splicing, the fibers are not coupled permanently. Instead, a uniquely designed self-contained assembly keep the two fibers aligned precisely. Moreover, an appropriate optical adhesive or gel is also used between the fibers. This arrangement enables the light to pass through two separate fiber strands. Following are a few types of mechanical splices available in the market:

- Rotary Splices

- Elastomeric splices

- V-Groove splices

- Snug Tube Splices

- Loose Tube Splices

What Makes Fusion Splicing a Better Choice?

Lower Cost

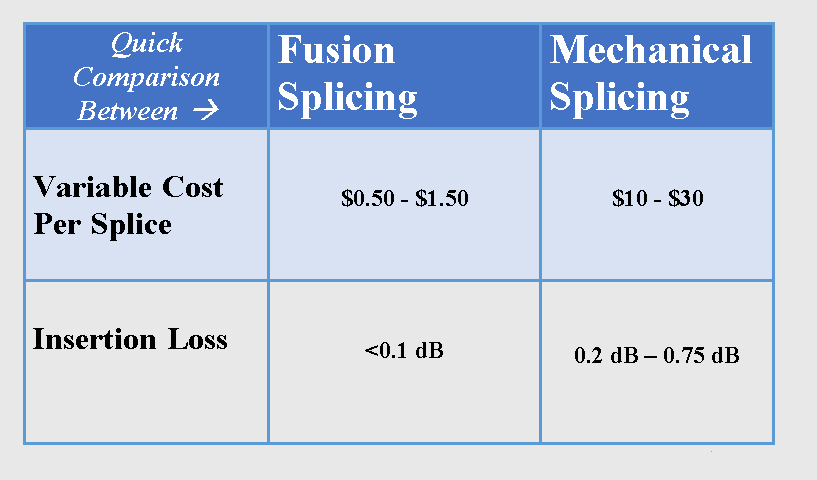

SFusion splicing usually costs more on account of upfront expenses. It is because of the necessary investment required for sourcing of a fusion splicing machine. However, it costs much cheaper in terms of cost per splice. In typical scenarios, you will spend $0.50 to $1.50 per splice. On the other hand, mechanical splicing doesn’t involve any upfront investment in equipment, but it comes at a higher cost i.e., around $10 to $30 per splice. Thus, mechanical splicing in an inefficient and expensive option available. A few years back, data center installers and operators were hesitant about trying fusion splicing just because of its higher setup expenses. However, things are quite better today. Now, the availability of fusion splicing tools at lower costs and their availability on rental basis has made the fusion splicing an attractive option.

Superior Performance

Mechanic splicing incurs higher insertion loss that remains around 0.2 dB to 0.75 dB. It is because, in this method, the two fiber are not joined physically but aligned and held in the right place. Here, insertion loss is the loss or depletion in signal power due to the incorporation of a splice in optical fiber. Fusion splicing is far more superior in terms of performance. Because in this splicing method, two fibers are welded together permanently, resulting in a continuous, physical connection between them. Thus; the insertion loss remain

Two Important things about Fusion Splicing:

I. Proper Handling of Protective Heat Sleeves Protective sleeves play a vital role in the prevention of newly incorporated splices. These sleeves shrink as heat is applied and the splice underneath remains protected against dust, temperature, moisture, and other environmental hazards. So, heat shrink sleeves must be stored in appropriate conditions. This will keep them useful for preventing fragile joints.

II. Proper Slack Management Proper slack management for ribbon fiber or 50µm, 900µm fibers must also be ensured. This will allow easy termination of spoiled connectors in the future.

Conclusion:

- Fusion splicing is a better solution available to join fibers

- The issue of its higher upfront cost can be managed through renting of equipment

- It is far more efficient in terms of cost per splice

- Fusion splicing brings the least impact on transmission efficiency

English

English

Deutsch

Deutsch

Espaniol

Espaniol