A fiber optic pigtail is usually a fiber optic cable with pre-terminated connectors at one end and exposed fibers at the other. A fiber optic pigtail is very practical for on-site terminations where fusion or mechanical splicers are used. Preterminated connectors offer several advantages over traditional epoxy, polished and quick connect connectors in terms of reliability, performance and ease of installation. In this article, we will look at the basics and different types of fiber optic pigtails.

Fiber Pigtail vs. Fiber Patch Cord: Understanding the differences

To clear up any confusion surrounding fiber optic pigtails and patch cords, it is important to understand their similarities and differences. By examining these aspects, a clearer understanding of their respective applications and functionalities can be gained.

The most important difference lies in the configuration of the fiber connection. Fiber optic pigtails are equipped with a single pre-terminated connector at one end, while the other end consists of bare fibers. Patch cords, on the other hand, are equipped with two or more factory-terminated connectors at both ends and have no exposed bare fibers.

Another distinguishing feature is the type of fiber cable used. For fiber optic pigtails, unsheathed cables with a diameter of 90μm are generally used. In contrast, patch cables generally use jacketed fiber cables with a diameter of 2.0 mm or 3.0 mm.

Thirdly, their applications also differ. Fiber optic pigtails are primarily used to enable fast fusion splicing applications. They are typically used to connect to devices that require splicing to create a permanent fiber optic connection. In contrast, patch cords are primarily used to make connections between patch panels, backbone networks and optical transceivers.

Finally, it should be noted that a fiber optic patch cord can be converted into two pigtails by simply cutting it into two pieces. This practice is often used because it is difficult to test a pigtail in the field. Accurately testing the undermined end of a pigtail becomes difficult until it is spliced to the device.

Types of fiber braids: a detailed exploration

There are different types of fiber pigtails, which are primarily distinguished by the fiber connection and the fiber type. This comprehensive overview looks at the different categories and highlights their properties and applications.

Classification of fiber types

Fiber optic pigtails are roughly divided into two categories: Multimode and single-mode fiber pigtails.

Multimode-Zigeunerschwänze

Multimode pigtails consist of 62.5 or 50-core multimode fiber optic cables that are terminated with multimode connectors. To classify them further, they can be subdivided into OM1 to OM5 pigtails. These classifications are based on the performance characteristics of the multimode fibers, including bandwidth and modal dispersion. Multimode pigtails are used for both short and medium distances.

Single-Mode-Zigeunerschwänze

Singlemode pigtails are made from 9μm OS1 or OS2 singlemode fiber optic cables terminated with singlemode connectors. These pigtails are designed for transmission over long distances and offer excellent signal quality with minimal loss. Singlemode pigtails are used in the majority of singlemode applications and are also used in certain multimode applications that require higher performance.

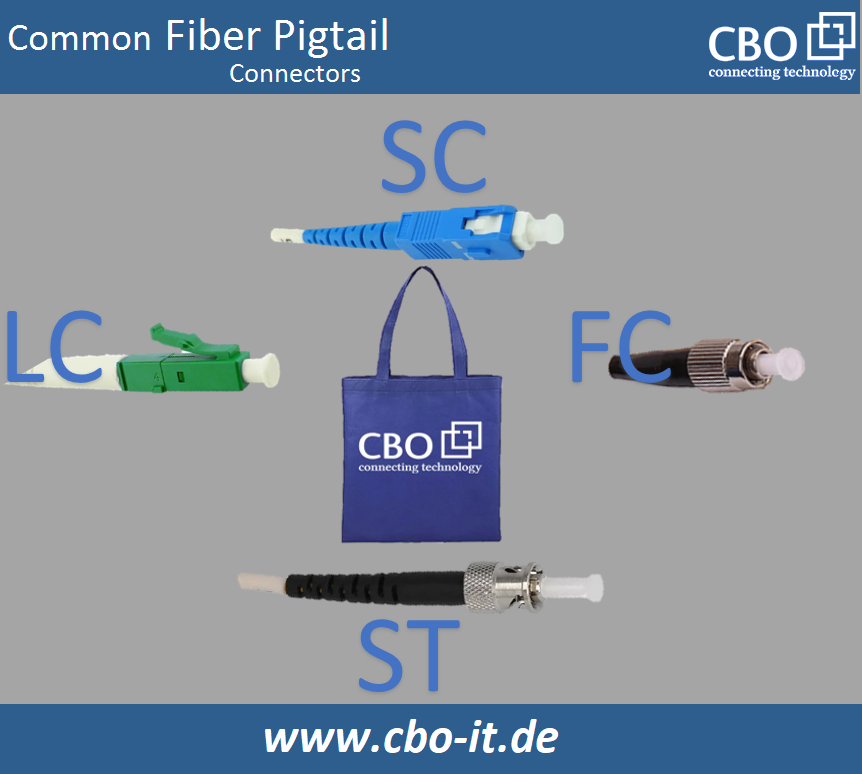

Differentiation between plug types

Fiber optic pigtails can be divided into different categories depending on the type of fiber optic connector used. Some common connector types are presented below;

Fiber optic pigtails can be divided into different categories depending on the type of fiber optic connector used. Some common connector types are presented below;

SC fiber pigtail

SC connectors, which stand for Subscriber Connector, are also known as square connectors or standard connectors. They contain a 2.5 millimeter thick, pre-blasted ferrule made of stainless alloy or zirconium dioxide. SC fiber pigtails are pre-terminated with SC connectors and are commonly used in both point-to-point (P2P) and passive optical networks (PON). Their cost-effectiveness, durability and ease of installation make them a popular choice.

LC fiberglass pigtail

LC connectors (Lucent Connector) are compact fiber optic connectors that have been specially developed for connections with high packing density and have an optimal form factor for such applications. They are a scaled-down version of the SC fiber optic connector and have a square PVC housing with a 1.25 millimetre ceramic ferrule. LC pigtails are supplied pre-assembled with LC connectors and are widely used due to their small footprint, reliability and ease of installation.

FC fiber pigtail

FC fiber pigtails take advantage of the metal housing of FC optical connectors, which contain a threaded structure and high-precision ceramic ferrules. They are widely used in various scenarios due to their robust design and reliable performance. FC pigtails are widely used in various industries due to their durability and stable connections.

ST fiber pigtail

ST fiber pigtails are similar to FC pigtails, but differ in the locking mechanism. Instead of threads, ST connectors use a special locking mechanism. The ST connector has an extended diameter of 2.5 mm and has a ferrule made of plastic, a stainless alloy or ceramic (zirconium dioxide). These pigtails are frequently used in telecommunications, industrial, medical and sensor applications.

Other variations

In addition to the fiber optic connector types mentioned above, there are other variants such as MU pigtails, E2000 pigtails and MPO pigtails, each tailored to specific requirements and applications.

Knowing the different types of fiber optic pigtails can help you make informed decisions when choosing the appropriate type for your needs, taking into account factors such as connectivity, performance and compatibility with your network infrastructure.

.png)

In the style of the Polish interface

The type of surface polishing of a fiber pigtail refers to the finishing of the ferrule of the connector. The most common types of polishing are presented below:

PC fiber pigtail

PC, the abbreviation for "physical contact", refers to a connector with a polished end face for physical contact. PC fiber pigtails are often used in the data and telecommunications industry. Due to their reliable performance, they are often used in multimode applications.

UPC-Faserschwanz

UPC is the abbreviation for "ultra-physical contact" and stands for a precise fiber optic connection technology. In contrast to PC pigtails, UPC pigtails have an improved physical contact with reduced air gaps and lower optical return loss (ORL).

APC fiber pigtail

APC is an acronym that stands for "Angled Physical Contact". These pigtails were developed to further reduce back reflections. APC connectors have an 8 degree angle on the ferrule. Fiber pigtails are often used in applications such as CATV, FTTx and other Wavelength Division Multiplexing (WDM) systems.

Classification of the application environment

Fiber optic pigtails can also be classified according to the application environment for which they are intended. Let's take a look at the main categories:

Normal interior braid

Regular indoor pigtails are the most common type and are used indoors where no additional protection is required. They are made of bare fibers and offer cost efficiency and a tight bend radius. However, they are not suitable for harsh environments or outdoor use.

Armored pigtail

Gepanzerte Pigtails verfügen über ein Edelstahlrohr, das in den Außenmantel eingeschlossen ist und Schutz vor schädlichen Einflüssen durch Nagetiere, das Gewicht anderer Kabel, Bauarbeiten usw. bietet. Sie bieten eine erhöhte Haltbarkeit und eignen sich für schwierige Installationsbedingungen.

Waterproof pigtail

Waterproof fiber pigtails are specially designed for harsh outdoor environments. They consist of robust fiber connectors, watertight devices with stainless steel reinforcement and armored PE jackets for outdoor use. These pigtails offer protection against twisting, pressure and damage from external influences. They are often used in applications such as communication towers and military installations.

Differentiation of the number of fibers

Fiber pigtails can have different numbers of fibers, from a single fiber to multiple fibers. Typically, single-fiber pigtails, such as simplex LC pigtails, consist of a bare fiber terminated with a connector. However, fiber pigtails with higher fiber counts, such as 2, 4, 6 and up to 72 fibers, are also available. Each fiber optic pigtail should meet the color coding requirements of TIA-EIA-598-A for proper identification.

Fiber construction categories

Finally, fiber pigtails can be divided into categories based on their fiber cable structure. The main types include:

Multi-fiber bundle pigtail

These pigtails consist of several fibers bundled in a single jacket and offer a practical solution for connecting several fibers at the same time.

Multi-fiber bundle pigtail

With ribbon pigtails, the fibers are arranged in a flat, ribbon-like structure, which enables efficient bulk fusion splicing and saves installation time in high-density environments.

0.9mm and 2.0mm / 3.0mm pigtail

These pigtails differ in their cable diameter. The 0.9 mm pigtail has a smaller diameter and is therefore suitable for applications where space is limited or a more inconspicuous installation is desired. The 2.0/3.0 mm pigtail, on the other hand, has a larger diameter and is therefore more robust and durable and suitable for outdoor or harsh environments.

Exploration of methods for splicing fiber braids

Two methods are generally used for splicing fiber optic pigtails: mechanical splicing and fusion splicing. Each method has its advantages and considerations so that the user can choose the most suitable technique depending on their specific requirements.

.png)

Let's take a closer look at these splicing methods.

Mechanical splicing

In mechanical splicing, the ends of two fibers are precisely aligned with a simple alignment device so that the light can pass from one fiber to the other. This technique has been used for many years and remains popular as it provides an instant and uncomplicated termination. Compared to traditional epoxy/polishing connector methods, fewer consumables are required, resulting in less waste. Mechanical splicing is cost-effective for individual splices, but can result in a higher overall cost per splice. It is an attractive option when simplicity and immediate results are paramount.

Fusion splicing

Fusion splicing is a technique in which high temperatures are used to fuse optical fibers due to the heat generated by the discharge between the electrodes. This method creates a virtually seamless splice, resulting in stronger connections with less loss and back reflection. Fusion splicing offers better performance compared to mechanical splicing. However, it requires skilled labor and a fiber optic fusion splicer, which means a higher initial investment. Despite the initial cost, fusion splicing offers a lower cost per splice in the long run.

How do you choose a suitable splicing method?

It is important to know that there is no standard termination method for fiber optic pigtails. The choice of splicing method depends on the situation and requires careful consideration of several factors. These include optical loss budget, time constraints and cost considerations. Users should evaluate their individual requirements and find a balance between these factors to determine the most appropriate splicing technique.

By carefully evaluating the requirements of the project, considering the desired splice quality and weighing the cost and time involved, users can make an informed decision on whether to opt for mechanical splicing or fusion splicing. Each method offers distinct advantages and allows flexibility and efficiency in terminating fiber pigtails according to individual requirements.

Conclusion:

In summary, it is important for anyone working with fiber optic networks to know the differences between fiber optic pigtails and patch cords. Some of the most important considerations to keep in mind include:

- Fiber optic pigtails have a pre-terminated connector and bare fibers on the other end, while patch cords have pre-terminated connectors on both ends.

- Fiber optic pigtails are typically used for high-speed fusion splicing applications, while patch cords are ideal for connecting between backbone networks, optical transceivers and patch panels.

- Fiber pigtails are available in different versions depending on fiber type (singlemode and multimode) and connector type (LC, SC, ST, FC, MU, E2000).

- Splicing methods such as mechanical splicing and fusion splicing offer different advantages in terms of cost, splice quality and performance.

- Fiber pigtail options also include multi-fiber bundle pigtails, ribbon pigtails and pigtails with different cable diameters (0.9 mm and 2.0/3.0 mm).

- When selecting a fiber optic pigtail, factors such as cost, performance, installation requirements and environmental conditions should be considered.

By considering these factors and making informed decisions, you can ensure efficient and reliable fiber optic connections that meet your specific network requirements.

English

English

Deutsch

Deutsch

Espaniol

Espaniol