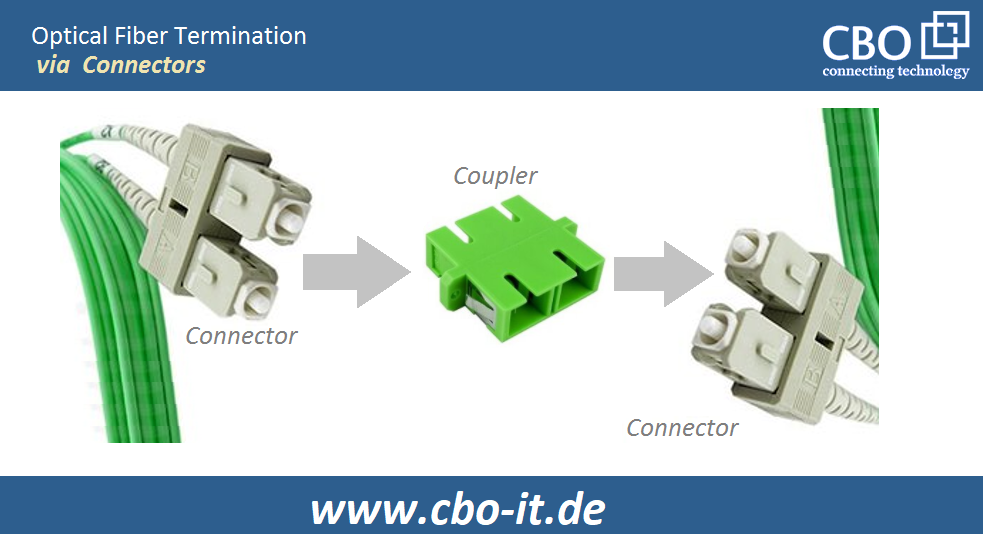

“Fiber-optic termination” is a term that represents the physical connection of an optical fiber cable to a device or a connection between two optical fiber cables. Termination is one of the most important aspects of link building within an optical fiber network. Without termination, we cannot connect two devices or two cables quickly and efficiently. Generally speaking, optical fiber cables are terminated via splicing technique or through connectors.

An Introduction to Connector Termination

Connectors are deployed at the end of an optical fiber cable in the process of termination. It’s been decades since the inception of the optical fiber technology and we have numerous types of connectors available on the market such as; FC, LC, SC, etc. fiber optic connector consists of three main components: the connector, the ferrule, and the coupling mechanism.

Traditional Polish and Epoxy Optical Connectors

Polish or Epoxy Fiber Connectors are widely used in the networking industry. You may observe that most factory-made connectors are polished or epoxy style because these types of connectors bring better reliability at a lower cost. The fiber is pasted into the connector with the help of epoxy and its end is polished through a special polishing film. Such conventional polish and epoxy fiber optic connectors are usually considered for high-density applications where connectors in bulk quantities are required.

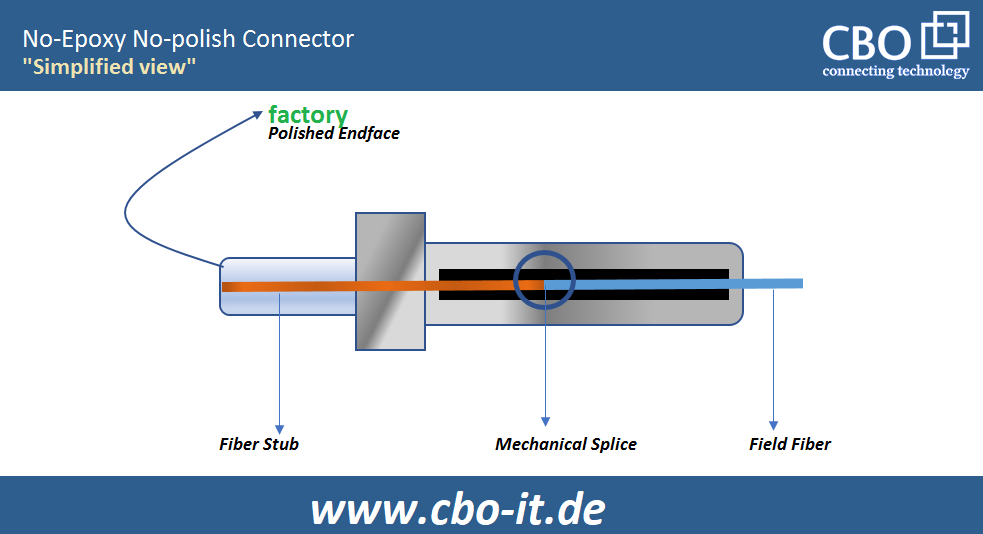

Quick Termination Optical Fiber Connectors

For quick termination optical fiber connectors, a factory-cleaved fiber stub is bonded into the ferrule whose end is polished to an APC/UPC or PC finish. Whereas, the cleaved mechanical field fiber resides inside the connector. The field fiber and the factory fiber stub are spliced mechanically. The following picture is showing the working principle of a quick termination type connector.

Splicing Type Termination

Splicing is another common type of field termination. No connectors are used in the splicing type of termination. Splicing termination can further be subdivided into two types; fusion splicing and mechanical splicing.

Fusion Splicing

In this type of splicing, termination is achieved with heat generated through an electrical arc or arc fusion. fusion splicing is more expensive than mechanical splicing because it requires a fusion splicer. For fusion splicing, all the protective coating of the optical fiber cable is removed and fibers are cleaved with the help of industrial-grade, high precision cleavers. Later, both fiber ends are aligned using a splicer machine and then the process of “welding” or “fusion” is carried out. Fusion splicing is recommended for the long-haul, high-performance, and outdoor single-mode network. Fusion splicing technique is often utilized in factories where optical fiber devices like amplifiers and fiber lasers are manufactured.

Mechanical Splicing

Mechanical splicing involves physical termination of two or more precisely aligned optical fibers which are held in the right place by the specially designed mechanical assembly. It is important to understand that no permanent connection exists between two or more mechanically spliced fibers. Mechanical splicing is relatively easy and fast. This kind of splicing is preferred when manpower and time are limited. Technicians usually prefer mechanical splicing for indoor transmission cable.

Splicing Termination vs. Connectors Termination

There is no such rule of thumb or standard to determine whether splicing termination or connector termination is better. Each type of termination has its pros and cons. You may get some assistance from referring to the drawbacks and benefits listed hereafter:

Pros and Cons of Connectors Termination

Pros

- Connector termination is cost-effective and timesaving in comparison with splicing termination

- Pre-manufactured connectors of different types are readily available on the market

- You won’t require any equipment such as a splicer machine

Cons

- Higher optical losses than that of splicer termination

- Connectors tend to fail more often than splices

Pros and Cons of Splicing Termination

Pros

- Splicing offers more reliable and stronger connections

- Lower insertion loss

- Different types of optical fiber cables can be spliced together

Cons

- Splicing requires advanced skills and sophisticated equipment

- Very high upfront cost

Conclusion

- Splicing and connectors are two fiber optic termination methods

- Termination through splicing is cost-effective and quick

- Splicing is a costlier option but has low optical loss than connectors

- Another option is pre-terminated optical fiber cables

- Splicing termination involves expensive equipment and skilled manpower

English

English

Deutsch

Deutsch

Espaniol

Espaniol