The Importance of Optical Transceivers Operating Temperature

The optical module or transceiver temperature is a very critical parameter that can affect the performance of the entire control system. A single malfunctioning module can lead to a catastrophic halting of important services and increased downtimes. As we all know, downtimes are just like bad dreams. Today, we are going to provide our readers with some useful information about the effect of alleviated module temperatures.

What is Module Temperature & who records it?

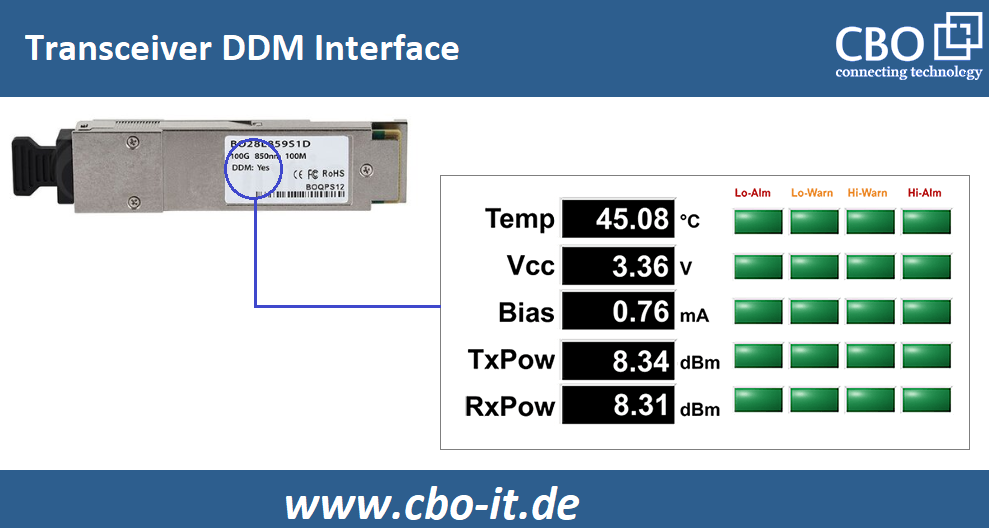

First of all, it is important to understand that every optical transceiver comes equipped with a bunch of diagnostic sensors including temperature sensors. These sensors monitor all the critical operating parameters of the module and temperature is also monitored on a real-time basis. Transceiver working temperature is an important parameter that should remain within the limits defined by the vendor. Operating a transceiver module beyond its documented operating temperature range can cause serious harm to the module.

Almost every optical transceiver comes equipped with DDM system or digital diagnostics monitoring system. This system monitors various parameters. User can access these parameters through module`s software interface to keep a check on the temperature, current, bias and other parameters.

What is the Normal Operating Temperature range of Transceivers?

Each transceiver module comes with a proper documentation package. You can easily find the vendor-defined operating temperature range for your module by consulting the user manual. Here, it is important to understand that the allowable operating temperature of any module depends on various factors including the form-factor and the material of construction. Generally speaking, optical transceivers can be operated over a temperature range wider than that of the copper modules.

Transceivers Classification based on Operating Temperatures

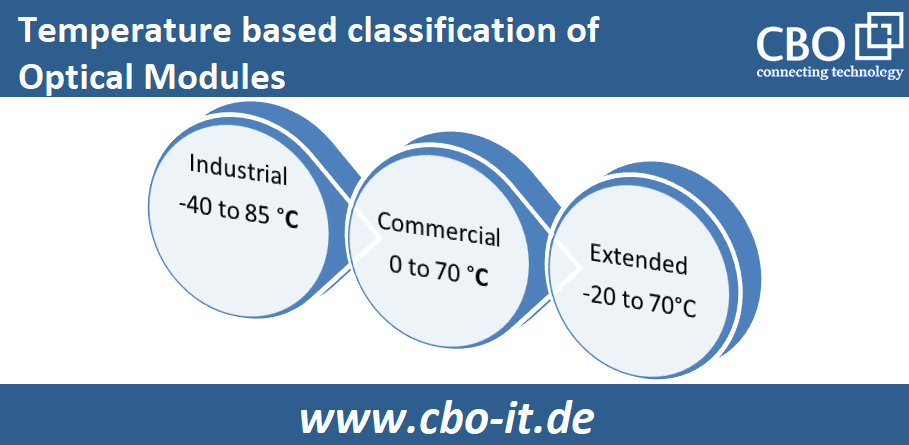

Based on operating temperature or allowable temperature we can segregate transceivers in three categories;

- Commercial category (0~70°C)

- Extended temperature category (-20°C~85°C)

- Industrial temperature category (-40°C~85°C)

The above mentioned three temperature ranges are denoted by; COM, EXT, and IND respectively. As you can observe, modules designed for industrial applications are more likely to withstand harsh operating temperatures. During the design phase of any network or data center, the prospective hardware devices including transceivers are scrutinized based on their operating temperature in addition to various other parameters.

Importance of Operating at Optimum Temperature

Well, operating beyond or below the vendor-defined temperature range is not a good practice. Initially, you might not notice but the efficiency and the integrity of the module decrease when it is operated at higher or lower temperatures. In some cases, the operation of a transceiver at an inappropriate temperature can even lead to its destruction. Now let us talk about the particular effects of hotter and colder operating temperatures.

Issues related to Higher Temperatures

There is a direct relationship between temperature and optical communication. It is a fact that higher temperatures can lead to the degradation of optical transmission. Moreover, operating a module at alleviated temperatures can lead to irreversible damage to the very sensitive electric circuitries which are used in the construction of optical modules. High operating temperatures are also related to the disordered operating and incorrect reception of signals. So, consider installing an HVAC system or another kind of cooling system in case if you are facing discrepancies in your network operation.

Issues related to Lower Temperatures

It is often considered that operating a module below its vendor-defined temperature range is not an issue – a statement that is incorrect principally. Lower temperatures can also affect the performance of your module. In case if you are operating in an area where the temperature falls below the freezing point of the water than you should use an extended range or industrial category modules.

Undefined Abnormal Operating Temperatures

Sometimes, network operators encounter indefinable temperature-related issues as they complain about alleviated temperatures. Here, it is important to understand that if you are facing such issues on one or two of your modules and the other ones are fine then there seems to be no issue with your air-conditioning system and the individual module should be checked. You can avoid such issues by acquiring your networking equipment from a reputable OEM or third-party vendor. Unfortunately, the optical transceiver market is flooding with cheap, poor quality products.

Another important thing to be mentioned here is the growing business of second-hand modules. Many network operators acquire second-hand equipment because it comes at a very low price. However, you should think twice before inking any such deal because second-hand products because you never know the actual reason because of which your prospective module ended up into the second-hand parts market.

Conclusion

Optical transceivers temperature is an important parameter and it should be recorded daily. In case if you are operating a few or even one module at alleviated temperature or at a temperature that is beyond the allowable temperature range than you should seek professional assistance immediately. However, each form factor comes with different types of internal hardware, and subsequently, each type of form-factor comes with a different operating temperature range.

English

English

Deutsch

Deutsch

Espaniol

Espaniol