Fiber patch cables or fiber patch cords are very popular and common in optical communication environments. These limited length cables are widely used in the interlinking of different network components and devices. To ensure 100% network uptime and system durability, it is important to understand and comply with all the instructions and precautions regarding the use of fiber patch cables. In this post ahead, we are going to provide our readers with some valuable information on the subject.

The scope of this article includes routine operations, maintenance, and recommended practices. Complying with the guidelines provided in this article will enable you for ensuring flawless operation of your network and for preventing you from undue downtime because of basic network layer faults.

Connection and Disconnection of Fiber Patch Cords

Fiber patch cords are designed to provide connectivity between different types of network devices including (but not limited to); fiber adapter panels, media converters, optical transceiver modules, and even switches, routers, or almost every component that is capable of sending or receiving information over fiber.

Consider that we have an optical fiber transceiver installed in a switch. Now, let us list the general steps required for safe connecting and disconnecting of fiber patch cords.

Connecting Fiber Patch Cords

- Remove the safety caps that are used to cover both frontend and backend connectors of the patch cord.

- Store the removed caps in an appropriate container and at the designated place.

- Now, remove the safety caps provided on the optical transceiver

- Insert the male cable connector into the female optical signal port of the transceiver

- Fix the fiber patch cord properly with the help of

Disconnecting Fiber Patch Cords

- Disable the interface in which the relevant transceiver module is installed

- Unplug the cable connector from the module

- Cover the transceiver with its safety plug

- Cover the optical cable connector using its safety plug

Following are a few important points which should be kept in mind during the connection and disconnection of optical fiber patch cords;

- Only skilled and experienced personnel with a thorough understanding of the network layout should be allowed to connect or disconnect patch cords

- Use of proper personnel protective equipment (PPE) must be observed. Generally, safety goggles and protective gloves are recommended. Moreover, wearing an anti-static wrist wrap is also necessary while working nearby or on active devices.

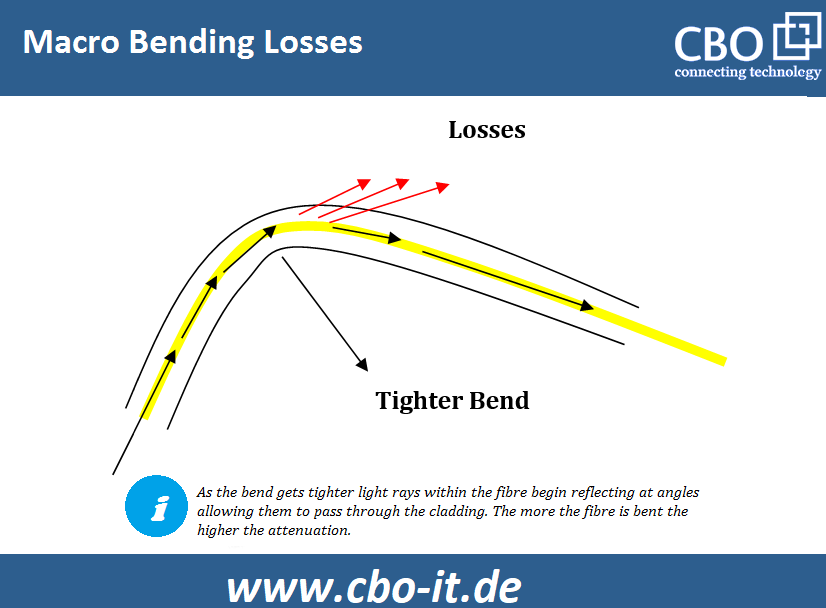

- Always adhere to the bending radius related recommendations from the manufacturer of the patch cable to avoid macro bending losses (as described in the diagram below)

- Never leave fiber patch cords hanging freely or scattered on the floor. Use appropriate fastening mechanisms to keep everything in order.

- For the safety of your eyes and vision, never ever look directly at any live cable’s endpoint.

- Remember! Frequent plugging and removal of fiber patch cords will result in the wear and tear of the connector`s end-faces.

- Adhere to the best housekeeping practices and keep your work area neat and clean.

Fiber Patch Cords Maintenance

In any optical fiber communication system, the routine maintenance of the fiber patch cords really matters. During routine maintenance, the following two factors must be kept in mind.

Cleanliness of Patch Cables

According to industrial experts, cleanliness plays a vital role in the integrity of optical fiber networks. In light of various surveys outcome, we can safely state that contamination is the biggest risk factor when it comes to fiber-optic networks. It is because the optical fiber communication light is used for carrying signals. Unfortunately, light can easily be intercepted by solid particles resulting in partial or complete arrest in the flow of information across a link. Here, it is important to understand that you must adhere to the vendor instructions while planning the cleaning activities of the fiber connectors.

Generally speaking; wet cleaning and dry cleaning are the two methods widely utilized for the cleaning of optical connectors. on the market, various cleaning solutions such as; pen cleaners, reel cleaners, foam swabs, and wipes are available.

Fiber Patch Cords Maintenance Tools

It is higher important to ensure you have a neat and clean optical fiber infrastructure. Cleaning existing and even new fiber patch cords before installation or insertion into a fiber coupler is important. There are various kinds of optical fiber cable maintenance tools available on the market and using these tools you can maintain your physical network in an optimum state.

- Wipes

The cleaning of optical fiber connectors through wipes is a very basic and easy method. On the market both dry wipes and IPA wipes are available. We believe, pre-saturated wipes are better as each unit of these wipes comes soaked in an appropriate amount of cleaning solution. On the other hand, the handling and usage of dry wipes are not as easy as the pre-saturated ones and with these wipes, the cleaning solution must be acquired separately.

- Cleaning Cassette and Tape

Cleaning cassette and tape is considered a fine alternative to alcohol-based and other cleaning solutions. This type of cleaners comes with room-grade cleaning media that can remove dirt, grease, oil, debris, and dust effectively from connecting end faces. The anti-scratch construction of these cleaners ensures the safety of the fiber. The cleaning media remains uncontaminated as it remains covered when not in use.

- Swabs

Swabs offer basic level cleaning. You can use swabs for cleaning contactor end faces, adaptors, and ferrules. Swabs work fine and offer access to difficult areas.

- Ferrule Cleaners

Ferrule cleaners are simple machines that offer connector cleaning through a mechanism that can be initiated easily by a push. The extendable tip of ferrule cleaners allows access to difficult to reach areas of recessed connectors. These cleaners are designed to ensure maximum performance against a broad range of contaminants. For optimum cleaning, you can rotate the ferrule cleaner by 180 degrees.

- Optical Microscope

The optical microscope comes in a variety of sizes and shapes. The connectors of these microscopes can easily be adjusted to suit the type of optical fiber connector being inspected.

When looking through an optical microscope you should be looking for visible signs of contaminants such as dirt, dust, oil, etc. After cleaning the connector, you should see a clean, regular, and perfect surface.

Proper Storage of Fiber Patch Cords

Fiber patch cords must be stored in a proper manner even if they are not in use. Avoid excessive bending or stretching your stock patch cords because frequent and excessive bending of cables can cause damage to its fiber. In a few cases, the damage to a fiber patch cord might be seen via the naked eye. However, in most cases, such damages stay unnoticed until the time when the cable is deployed.

Storage temperature is another very critical aspect to be discussed here. In this regard, you must adhere to the storage instruction as provided by the vendor of your fiber patch cords. Storing optical fiber cables in low temperatures can result in microscopic fiber deformations – a big cause of high attenuation.

Conclusion

Fiber patch cords play a vital role in the construction and operation of an optical fiber communication network. Proper handling and maintenance of fiber patch cords are important for flawless network operations. It is crucial to adhere to the vendor`s instructions regarding the installation, cleaning, and storage of optical fiber cables.

English

English

Deutsch

Deutsch

Espaniol

Espaniol