Have you ever purchased fiber connectors? The terms “UPC Polish”, “APC Polish” and “PC Polish” are frequently heard by those who shop for optical fiber connectors. Here, it is important to understand that these terms are related to no-epoxy no-polish (NENP) type connectors only. The other type of connectors is called epoxy-and-polish connectors (EP) connectors. Today, we are going to discuss these terms and the difference between different polish types. Hopefully, our readers will not find these terms confusing anymore. Please note that this article is related to different connector polishing styles only and not about the different type of optical fiber connecters (like LC, SC, etc.)

Epoxy-and-Polish Connector Vs. No-epoxy No-polish Connectors

EP connectors are the ones that are prepared for application by the end-user. On the other hand, No-epoxy no-polish (NENP) connectors are shipped for quick deployment. EP connectors are needed to be polished manually before they can be installed for optical fiber transmission. Whereas, the NENP type connectors are precisely polished by the vendor in either UPC, PC, or APC style. Moreover, these connectors come equipped with a pre-installed fiber stub inside the ferrule and the field fiber is mechanically spliced with that stub. Unfortunately, EP connectors are not shipped with a stub.

What are Connector Polishing Styles?

APC, PC, and UPC all these terms refer to the polish style of the ferrules that are found inside fiber optic connectors. As discussed earlier, no-epoxy no-polish type connectors come with a factory-installed fiber stub. So, it’s the ferrule of a connector that maintains the fiber stub in an optimum orientation to ensure a robust physical contact for optimum data transmission. Thus, the fiber stub or the end-face and the ferrule all are polished in either PC, UPC, or APC style. However, polishing can also be done manually and the use of manually polished connectors is still quite common in the industry.

Is Polishing Important?

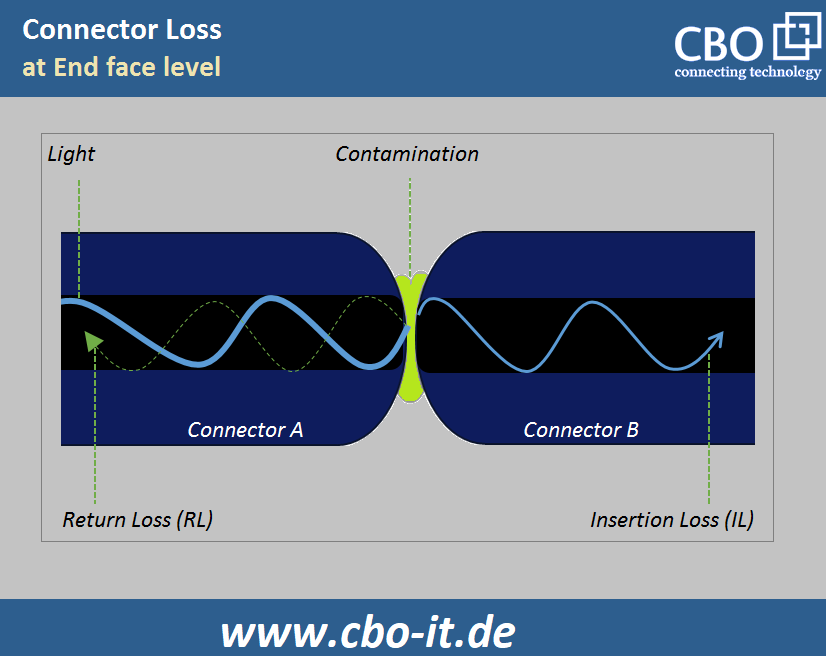

Yes! Polishing is very important for optical fiber connectors because it limits the reflection of light that occurs at the point where a fiber terminates into a connector. This reflection of light towards the source is called Return Loss. Here, it is also important to learn about Back Reflection. Concerning an optical fiber link, back reflection represents the total accumulated light reflected and traveled to the sources.

Ferrule polishing is the only solution that works for the curtailment of back reflection and return loss. We can minimize the loss by joining two perfectly aligned and completely identical fiber cores employing properly finished or polished connectors. Now, as we have developed a fair understanding bout fiber polishing and its importance, let us proceed to discuss the most commonly used ferrule polish types.

Connection Polish Types

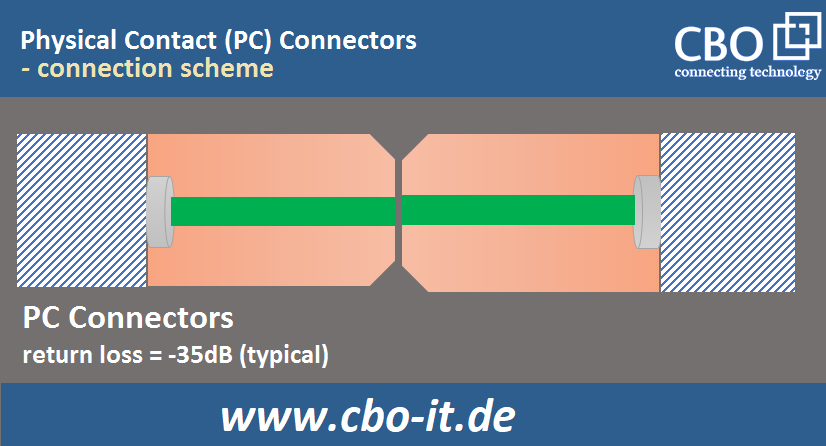

PC Fiber Connector

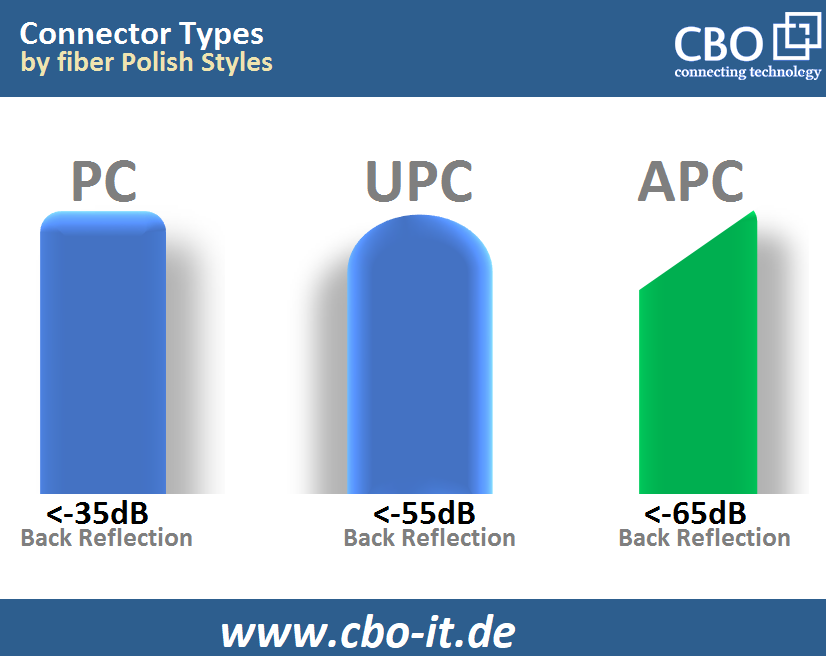

PC or physical contact polishing style is the most common polish style that is usually found on OM1 and OM2 multimode fiber. PC fiber connectors are designed to minimize the air gap between the connector surfaces. In this polish style, the ferrule of the connector is shaped like a slightly cylindrical head. This design helps in minimizing the air gap between the two surfaces of connectors that come into contact. Through physical contact polish style, the return loss can be minimized down to -40dB – much better than the typical loss of approximately 4% or -14dB that remains unavoidable when we connect two unpolished connectors. These days PC polish style is considered obsolete and the UPC style is becoming a preferred choice.

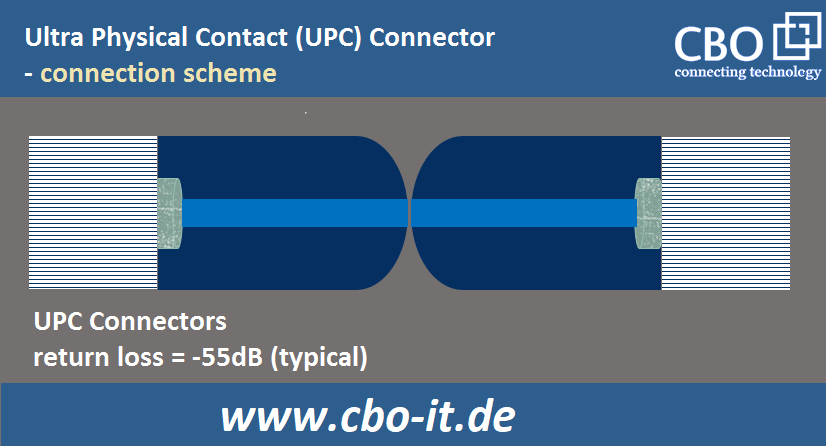

UPC type Fiber Connectors

style. Connectors shipped with UPC polish style comes with extended polishing and a better surface finish. Ultra-Physical contact polish style with around -50dB return loss is a much better choice in comparison with the physical contact polish style. However, it is not as good as the APC polish style. Moreover, the overall performance of the connector degrades because of frequent connections and disconnections. Here, it is important to note that the UPC connectors can perform equally well or even better when it comes to insertion loss.

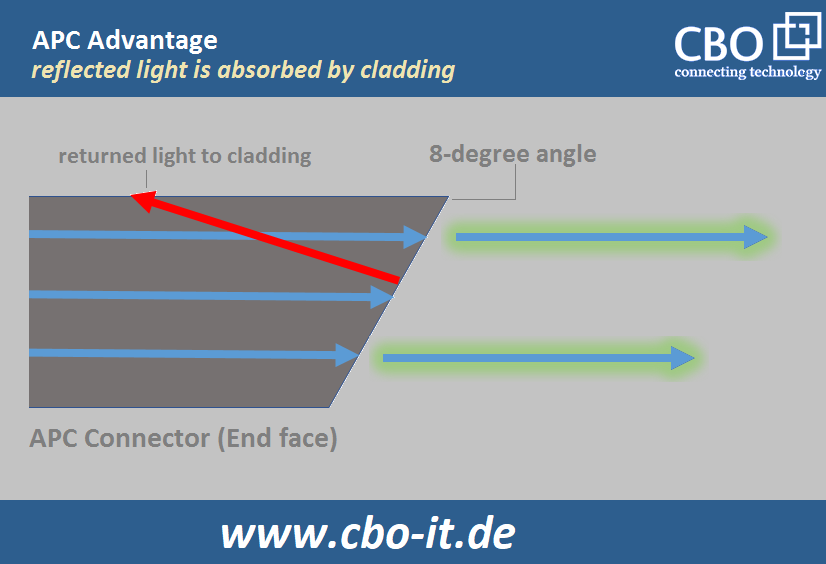

APC Fiber Connector

Angled physical contact connectors are designed to minimize the back reflection even more efficiently. The ferrule end-face of these connectors is polished at an angle of 8 degrees. Thus, any light that reflects at the point of termination is reflected at a steep angle so it cannot travel far towards the source. in other words, this polish style forces the light to reflect into the cladding rather than the sources. However, even APC fiber connectors cannot eliminate the inherent losses and in typical operating conditions, the minimum return loss remains around -65dB.

APC Vs. PC Vs. UPC

By now, we have learned about the construction of these three types of optical fiber connectors. Let us proceed with the major differences between these connectors in terms of applications, appearance, and performance.

Appearance

- PC and UPC connectors are polished without angle

- UPC end-face has a slight curvature

- The end-face of the APC connectors is polished at an angle of 8 degree

- PC/UPC connectors are offered in blue color

- APC connectors are offered in green color

Performance

- PC connectors are not preferred because of their higher back reflection loss

- UPC connectors offer better performance than PC connectors

- In terms of insertion loss, UPC connectors tend to outperform APC connectors

- APC connectors offer superior performance in terms of return loss

Applications

- APC connectors are preferred in FTTx and other WDM systems

- PC connectors are generally utilized in the telecom sector

- UPC connectors are a popular choice for TV and data systems

- PC and UPC connectors are still used in applications where return loss can be sustained

- PC connectors are not considered for bandwidth-intensive applications

- APC connectors cost higher than PC and UPC connectors

Conclusion

Connectors with physical contact (PC) polish style are not recommended for demanding and extensive applications. APC connectors are preferred for applications where maximum precision and minimum losses are desired. UPC connectors offer better performance than PC connectors. In terms of insertion loss, UPC connectors are superior to APC connectors. However, APC connectors are the best type of connector available and that’s why these connectors cost more than the other types.

English

English

Deutsch

Deutsch

Espaniol

Espaniol